High Purity Nickel Foil Ni200 Ni201

Short Description:

Nickel 201 Plate Suppliers

NICKEL 201 SHEET SUPPLIERS

LEADING MANUFACTURER OF NICKEL ALLOY 201 SHEET, NICKEL 201 COILS, NICKEL 201 POLISHED PLATE AND NICKEL 201 COLD ROLLED PLATE IN INTERNATIONAL STANDARDS.

Highly Acclaimed Manufacturer & Exporter of Nickel 201 Coils, Nickel Alloy 201 Plate, JIS NW 2201 Plate, ASTM B162 UNS N02201 Plate, Nickel 201 Cold Rolled Plates, Alloy 201 Polished Plate, Nickel 201 Shim Sheet.

We are trustworthy stockist of ASME SB162 UNS N02201 Sheets, DIN 2.4068 Plate, Nickel 201 Cold Rolled Plate, Nickel 201 Clad Plate, Nickel 201 Rolling Sheets, Nickel 201 Strips, Nickel Alloy 201 Annealed Strip and Nickel 201 Flat Sheet.

We are a leading manufacturer and exporter of Nickel 201 Plates in China. We have well reputed name as Nickel 201 Sheet Suppliers and Nickel 201 Plate Suppliers. Nickel 201 Sheets offer Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations. Nickel 201 Sheets has extremely low work and a low annealed rigidity – toughening rate. The elemental restrictions of Alloy 201 Plates are combined into one, dual-certified chemistry resulting in a single alloy with the desired characteristics.

Nickel Alloy 201 Sheet is designated as UNS N02201 and Werkstoff Number 2.4068. Our offered Alloy 201 Plate exhibit good resistance to corrosion in acids and alkalis and is most useful under reducing conditions. All hot working and cold working practices can be utilized when shapingNickel Alloy 201 Plate. Due to its improved ductility and resistance to graphitisation this Nickel Alloy 201 Coil is used for combustion boats, plater bars, caustic evaporators, and electrical components. Nickel 201 Clad Plate is approved for service up to 1230° F. Melting point of Nickel 201 Strips & Nickel UNS N02201 Shim Sheet is 2615-2635° F. Nickel Alloy 201Rolling Sheets can be cold formed by standards methods.

ASTM B162 UNS N02201 Plate is normally limited to service at temperatures below 600° F. At higher temperatures, Nickel 201 Coils can suffer from graphitization which can result in severely compromised properties. WNR 2.4068 Sheets are approved for the construction of pressure vessels and components under ASME Boiler and Pressure Vessel Code Section VIII, Division 1. Alloy 201 Hot Rolled Plate is approved for service up to 600° F. Alloy 201 Coils Melting point is 2615-2635° F and used in food handling machinery.

Nickel 201 Diamond Plate also known as a floor plate, chequered plate, and tread plate is a type of metal designed with lines on one side, with the reverse side being featureless or a regular pattern of raised diamonds. We specialize in Nickel Alloy 201 Plate. We have huge ready stock of Nickel 201 Hot Rolled (HR) Sheet, Nickel 201 Coils, Nickel 201 Cold Rolled (CR) Plates, Nickel 201 Shim Sheet, Nickel 201 Plain Sheets, Nickel 201 HR Plates, Nickel 201 Perforated Sheets & Plates, Nickel 201 Galvanized Plates & Sheets in our inventory at best price. Nickel Alloy 201 sheet thickness varies and it can also be acquired based on the requirement of the client.Get Nickel 201 Plate Price in India.

At the time of manufacturing superior technology, as well as extensive quality control from steelmaking to finishing, assure the stable production of DIN 2.4068 Plate in uniformly of excellent quality. We apply the process of surface finishing to our Nickel Alloy 201 Plate by pickling or buff-polishing. Nickel Alloy 201 Strips levels of finishing & cut can be adjusted according to customer requirements. Alloy 201 Plate is available in the form of Sheet, Plain Sheet, Shim Sheet, Foils, Coils, Rolls, Strip, Flats, Clad Plate, Rolling Sheet, Flat Shim, Rolling Plate, and Flat Sheet. Nickel 201 Plate Weight Calculator allows you to calculate an estimate of the weight of various sizes of Nickel Alloy 201 plates based on shape and dimensions.

Nickel 201 Plate Specifications

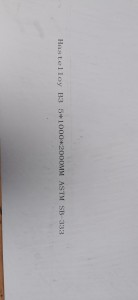

| Specifications | ASTM B162 / ASME SB 162 |

| Nickel 201 Sheet AMS | AMS 5553 |

| Size | 1000 mm x 2010 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2010 mm x 2010 mm, 2010 mm x 2010 mm |

| Thickness | 0.1mm to 12 mm Thk |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Nickel Alloy 201 Plate Types

| AMS 5553 Nickel 201 Sheet | Nickel 201 AMS 5553 Plate |

| Nickel 201 Hot Rolled Plates | Nickel 201 Cold Rolled Plates |

| Nickel Alloy 201 Hot Rolled Plate | Nickel 201 Cold Drawn Sheet |

| 2B finish Nickel 201 sheet | Cut to size Nickel 201 plate |

| Nickel 201 Galvanized Sheets | Nickel 201 Ring Coils |

| Cold rolled Nickel 201 sheet | Hot rolled Nickel 201 plate |

| 2B BA Hairline Mirror finish Nickel 201 plates | Brush Nickel 201 Plate |

| Nickel WERKSTOFF NR. 2.4068 Foils | Polished Nickel 201 Sheet |

| Perforated Nickel 201 Sheet | Nickel 201 2B Plate |

| ASTM B162 UNS N02201 Steel Plate | Nickel 201 Cold Rolled Coils |

| 8K Mirror Finish Nickel 201 Sheet | Hairline Nickel 201 Sheet |

| No.4 Nickel 201 Sheet | Nickel 201 Diamond Plate |

| Thin Nickel 201 Sheet | Nickel 201 Rolls Sheets |

| Nickel 201 Design Sheet | Nickel 201 Expanded Sheet |

| 201 Alloy Shim Sheets | Nickel Alloy 201 Sheets |

| Nickel 201 Clad Plate | Nickel 201 Strip |

| Nickel 201 Shim Stock | Nickel 201 Quarto Plate |

| Nickel 201 Polished Plates | Nickel 201 Perforated Sheet |

| Cut to Size Nickel 201 Sheet | Nickel 201 Annealed Strip |

| Bright Annealed Nickel 201 Sheet | Nickel 201 Corrugated Sheet |

| Nickel 201 HR Sheets | ASTM B162 Nickel 201 Sheets |

| Nickel 201 Floor Sheet | Nickel 201 Diamond Sheet |

| Nickel 201 Coils | Nickel 201 Chequered Plate |

Equivalent Grades of Nickel 201 Sheet Plate

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS | BS | GOST | AFNOR |

|---|---|---|---|---|---|---|---|

| Nickel 201 | N02201 | 2.4068 | LC Ni 99.2 | NW 2201 | NA 12 | НП-2 | – |

Nickel 201 Sheet Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 201 | 0.2 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Alloy 201 Sheet & Plate Mechanical Properties

| Grade | Density | Tensile Strength | Yield Strength (0.2%Offset) | Melting Point | Elongation |

|---|---|---|---|---|---|

| Nickel 201 | 8.9 g/cm3 | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 1446 °C (2635 °F) | 45 % |

Nickel 201 Sheet Size

| PRODUCT FORM | ALLOY | DIMENSION |

|---|---|---|

| Strip; cold rolled, annealed | NICKEL 201 (99.0 Ni min) | 0.10×56.5 mm x coil, 0.05 kg/m |

| Strip; cold rolled, annealed | NICKEL 201 (99.0 Ni min) | 0.15×3 mm x coil, 0.004 kg/m |

| Strip; cold rolled annealed | NICKEL 201 (99.0 Ni min) | 0.15×5 mm x coil, 0.007 kg/m |

| Strip; cold rolled, annealed | NICKEL 201 (99.0 Ni min) | 0.15×7 mm x coil, 0.009 kg/m |

| Strip; annealed | NICKEL 201 /201 (99.0 Ni min) | 0.15×150 mm x coil, 0.20 kg/m |

| Sheet; cold rolled, soft annealed, descaled, sheared | NICKEL 201/201 (99.0 Ni min) | 3.0x1201x3000 mm, 95.9 kg/pc |

Nickel 201 Plate Thickness

| Alloy 201 PLATE METRIC DIMENSIONS | ||

|---|---|---|

| SURFACE FINISH | THICKNESS (MM) | WIDTH (MM) |

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Nickel 201 Plates Imperial Dimensions

| Width (in) | Surface finish | Gauge (in) |

|---|---|---|

| max. 72* | 2B – Cold rolled, heat treated, pickled, skin passed | 10–24 |

| max. 60 | 2D – Cold rolled, heat treated, pickled | 12–24 |

| max. 48 | BA Mexinox only | 18–28 |

| max. 60 | Polished (not brushed) | 11–24 |

| max. 48 | Temper rolled Mexinox only | 13–29 |

Material Grade

| Material | ASTM A240 Standard | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 410S 430 904L |

| ASTM A480 Standard | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615,S33228, S38100, 304H, 309H, 310H, 316H, 309HCb, 310HCb, 321H,347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904,N08926, S31277, S20161, S30600, S30601, S31254, S31266,S32050, S32654, S32053, S31727, S33228, S34565, S35315,S31200, S31803, S32001, S32550, S31260, S32003, S32101,S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 Standard | SUS301L,SUS301J1,SUS302,SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 Standard | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu,SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2,SUS305, SUS309S, SUS310S, SUS312L, SUS315J1, SUS315J2,SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1,SUS316J1L,SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2,SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS329J4L, SUS405, SUS410L, SUS429, SUS430, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L,SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403,SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Product Specification

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments, Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware, architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasives. The most popular finishes | Milk & Food processing facilities, Hospital Equipment, Bath-tub |

| No. 8 | 0.5mm~2.0mm | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior-Exterior decoration forbuilding |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

N |

Cu |

Nb |

|

201 |

≤0.15 |

≤1.0 |

5.50-7.50 |

≤0.05 |

≤0.03 |

16.00-18.00 |

3.50-5.50 |

- |

- |

0.05-0.25 |

- |

- |

|

202 |

≤0.15 |

≤1.0 |

7.50-10.00 |

≤0.05 |

≤0.03 |

17.00-19.00 |

4.00-6.00 |

- |

- |

0.05-0.25 |

- |

- |

|

301 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

16.00-18.00 |

6.00-8.00 |

- |

- |

≤0.1 |

- |

- |

|

302 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

≤0.1 |

- |

- |

|

303 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.2 |

≥0.15 |

17.00-19.00 |

8.00-10.00 |

≤0.6 |

- |

≤0.1 |

- |

- |

|

304 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304H |

0.04-0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304N |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

0.10-0.16 |

- |

- |

|

304J1 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

6.00-9.00 |

- |

- |

- |

1.00-3.00 |

- |

|

305 |

≤0.12 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

10.50-13.00 |

- |

- |

- |

- |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

22.00-24.00 |

12.00-15.00 |

- |

- |

- |

- |

- |

|

310S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

24.00-26.00 |

19.00-22.00 |

- |

- |

- |

- |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

12.00-15.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316N |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

0.10-0.16 |

- |

- |

|

316Ti |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

11.00-14.00 |

2.00-3.00 |

≥5C |

- |

- |

- |

|

317L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

11.00-15.00 |

3.00-4.00 |

- |

- |

- |

- |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

5C-0.7 |

- |

- |

- |

|

347 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

10C-1.10 |

|

347H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

8C-1.10 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

21.00-24.00 |

4.50-6.50 |

2.50-3.50 |

- |

0.08-0.20 |

- |

- |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

24.00-26.00 |

6.00-8.00 |

3.00-5.00 |

- |

0.24-0.32 |

- |

- |

|

904L |

≤0.02 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

19.00-23.00 |

23.00-28.00 |

4.00-5.00 |

- |

- |

1.00-2.00 |

- |

|

C276 |

≤0.02 |

≤0.05 |

≤1.0 |

- |

- |

14.00-16.50 |

Other |

- |

- |

- |

- |

- |

|

Monel400 |

≤0.3 |

≤0.5 |

≤2.0 |

- |

≤0.024 |

- |

≥63 |

- |

- |

- |

28-34 |

- |

|

409L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

- |

- |

- |

- |

- |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

410L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

420J1 |

0.16-0.25 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

420J2 |

0.26-0.40 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

430 |

≤0.12 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

436L |

≤0.025 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

- |

- |

- |

- |

- |

- |

|

439 |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

440A |

0.60-0.75 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440B |

0.75-0.95 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440C |

0.95-1.2 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

441 |

≤0.03 |

0.2-0.8 |

≤0.7 |

≤0.03 |

≤0.015 |

17.50-18.50 |

- |

≤0.5 |

0.1-0.5 |

≤0.025 |

- |

0.3+3C-0.9 |

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage.

Identification labels are tagged accordingto standard specification or customer’s instructions.

Special packing is available as per customer’s requirement.

Stainless Steel Coil Package

Stainless Steel Sheet / Stainless Steel Plate Package

Stainless Steel Strip Package

Shipment Package

Our company is based in Wuxi, gathering city of industrial stainless steel in China.

We specialized in stainless coils, sheets and plate, stainless steel pipe and fittings, stainless steel tubes, and also aluminum products and copper products.

Our products have been highly praised by our clients from Europe, America, the Middle East, African and Southeast Asia. We will offer competitive products and comprehensive service to customers.

Stainless Steel Grade: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316L, 321, 347, 410, 416, 420, 430, 430F, 440, 440c,

Alloy Grade :Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, High Speed Steel, Mild Steel, Aluminium, Alloy Steel, Carbon Steel, Special Nickel Alloys

In form of : Round Bars, Square Bars, Hexagonal Bars, Flat Bars, Angles, Channels, Profiles, Wires, Wire Rods, Sheets, Plates, Seamless Pipes, ERW Pipes, Flanges, Fittings,etc.

Q1: What is stainless?

A: Stainless means no marks on the steel surface, or a kind of steel that is not damaged by air or water and that does not change color, spotless, resistant to staining, rusting, the corrosive effect of chemicals.

Q2: Does stainless mean no rusting?

A: No, stainless means not easy to get stained or rusty, it has speical ability to reisist staining, rusting and corrosion.

Q3: Do you supply stainless steel sheets?

A: Yes, we supply different types of stainless steel sheets, with thickness ranges from 0.3-3.0mm. and in different finishes.

Q4: Do you accept cut to length service?

A: Of course, customer’s satisfaction is our top priority.

Q5: If i have a small order, do you accept small order?

A: Not a problem, your concern is our concern, small quantities are accepted.

Q6: How can you guarantee your product quality?

A: First, from the very start, we have already implemented a spirit to their mind, that is quality is life, our professional workers and staffs will follow up every step till the goods packed well and shipped out.

Q7: Will you pack the products?

A: Professional people do professional packing, we have different types of packing optional to customers, economic one or better one.

Q8: What do you need to know from customer before accurate quotation?

A: For an accurate quotation, we need to know grade, thickness, size, surface finish, color and quantity of your order, and also the destination of the goods. Customized product information will be needed more, like drawing, layout and plan. Then we will offer competitive quotation with the above information.

Q9: What kind of payment term you accpet?

A: We accept T/T, West union, L/C.

Q10: If this is a small order, will you delivery the goods to our agent?

A: Yes, we are born to solve problems of our customers, we will get the goods safely to your agent’s warehouse and send you the pictures.

Q11: Do you just make flat sheet? I want to make a fabrication for my new project.

A: No, we mainly produce stainless steel flat sheet surface treatment, at the same time, we manufacture customized metal finished product as per customer’s drawing and plan, our technician will take care of the rest.

Q12: How many coutries you already exported ?

A: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Iran,

Turkey, Jordan, etc.

Q13: How can I get some samples?

A: Small samples in store and can provide the samples for free. Catalgue is available, most

patterns we have ready samples in stock. Customized samples will take about 5-7days.

Q14: What is the delivery ?

A: Sample order’s delivery time is 5- 7 days. Container orders are about 15-20 days.

Q15: What is the application about your Products?

A: 1.elevator door/cabin or and escalator’s side-wall.

2.Wall cladding inside or outside meeting room/ restaurant.

3.Facade when cladding over something, like columns in the lobby.

4.Ceiling in the supermarket. 5.Decorative draws in some entertainment places.

Q16: How long Can You Guarantee for This Product/Finish?

A: Color guarantee for more than 10 years. Original materials quality certificate can

be provided.